Product Description

AISI316L/304 (material proof can be provided) is used in the inner chamber, jacket and indoor pipeline of the sterilizer to ensure the reliable quality and durability of the main body of the sterilizer;

The main body is manufactured using advanced welding technology and testing means. The inner surface: electrolytic polishing, pipeline electrolytic polishing, which meets the process requirements of food grade;

The whole sterilization process is automatically controlled by microcomputer, which has a high degree of automation. The color touch screen can dynamically display the working temperature, pressure, time and sterilization stage Parameter, operation is more intuitive and convenient;

The equipment is equipped with multiple sterilization procedures (solid, liquid, metal, fabric, B-D test, etc.), and the working parameters can be set according to the actual situation of the user; meanwhile vacuum detection, vacuum leakage rate is less than 0.13Kpa/min;

Multi-channel steam intake, multi-stage heating, more uniform temperature distribution, lower steam

energy consumption;

Four-sided V-shaped cavity base design, excellent drainage performance.

Notes: Self-produced steam sterilizer with steam generator and water pump, the device has the following functions:

The function of automatic water intake and replenishment of the water pump makes the water level in the steam generator controlled within a reasonable range.

When the water level in the steam generator reaches the lowest value, the power supply of the electric heat pipe can be cut offff and the alarm will be given;

The pressure controller is used to control the pressure in the steam generator, and the safety valve is used to protect the overpressure.

Product Details

| Model |

BXW-0.6JDM(-D) |

| Volume [m³] |

0.6 |

| Sterilization Size [mm] |

1180×610×910 |

| Power Supply [V, Hz] |

380, 50 |

| Steam Source |

Own/External |

| Inner Cavity Design Pressure |

-0.1~ 0.3MPa |

|

Inner Cavity Work Pressure

|

-0.1/0.25MPa |

|

Jacket Design Pressure

|

0.3MPa |

| Jacket Work Pressure |

0.25Mpa |

| Inner Cavity Water Pressure test |

0.39Mpa |

| Jacket Water Pressure Test |

0.52Mpa |

| Design Temp. |

144℃ |

| Sterilization Temp. |

105℃~139℃ |

| Temp. Uniformity |

±1℃ |

| Limited Vacuum |

-94.3KPa |

|

Leakage Rate

|

≤1.3KPa-10min |

|

Temp. Difference(External Temp. & Ambient Temp.)

|

15℃

|

|

Power [kW]

|

2.4 |

|

Housing Dimensions [mm]

|

1440×1280×1940 |

| Gross weight [kg] |

1200 |

| Package size [mm] |

1590×1426×2300

|

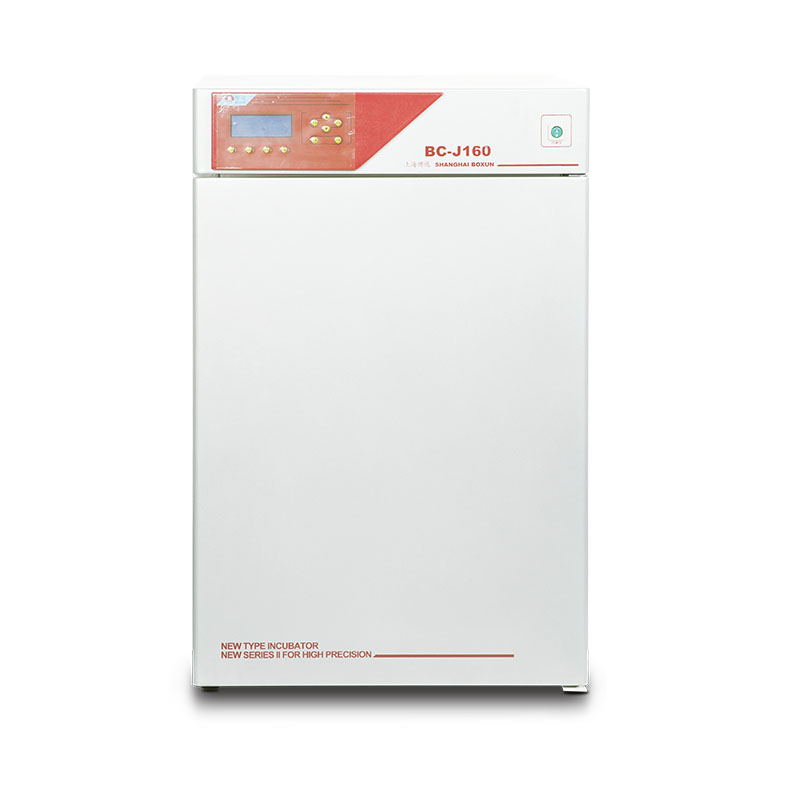

Product Display

Packaging Details

1.Standard exporting package.

2.Cartons packaged with wooden pallet.

3.As so customized specifications such as logo or others.

Delivery Time

20 days

FAQ

1. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

2.what can you buy from us?

Autoclave,Incubator,Drying oven,Test Chamber,Clean bench and other laboratory equipment.

3. why should you buy from us not from other suppliers?

We are a professional manufacturer of laboratory equipment and life science instruments. We have 25 years of design and R & D experience and focus on control solutions of temperature and humidity.

4. what services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW;

Accepted Payment Type: T/T;

Tel

: 86-021-56980111

Tel

: 86-021-56980111 Schreiben Sie uns eine E-Mail

: export@shbxyl.com

Schreiben Sie uns eine E-Mail

: export@shbxyl.com

Deutsch

Deutsch English

English français

français русский

русский español

español português

português 日本語

日本語 한국의

한국의 ไทย

ไทย 中文

中文

Nationale einheitliche Hotline :

Nationale einheitliche Hotline : Schreiben Sie uns eine E-Mail

:

Schreiben Sie uns eine E-Mail

: Firmenanschrift :

Firmenanschrift : export@shbxyl.com

export@shbxyl.com

IPv6-Netzwerk unterstützt

IPv6-Netzwerk unterstützt